Due to some scheduling difficulties, we were finally able to use the typewriters on Friday. Our Journal topics for Fridays are "freewrites" so it was perfect opportunity to have them used. They could take all the time they needed to get comfortable with the typewriter. I front-loaded instruction on Thursday with a small presentation all bout the CTP and some of the data behind using the typewriters. The Thursday presentation primed them for the excitement on Friday.

The sound of 20 typewriters tapping away is really very familiar. For three years my work day has been filled with the whack of type bars against papers and platens. I have grown so accustomed to the sound that the absence is more deafening than the presence.

Of all the classes who have used typewriters, this group was the most enthusiastic. They really loved giving it a chance. This group of kids really paid attention to the into diagram and had very little trouble getting started. You know something is a success when it's time to switch activities and their is an audible groan of disapproval. I think that over the course of the school year the typewriter love will increase.

I mention 20 typewriters because I have decided to keep 20 in constant rotation; moving out typewriters that become damaged or a little worn out. I have enough of a back stock that I can be a few months behind on repairs and still have 20 completely working typewriters. As always Royals make up a large portion of what students use, but there seem to be more and more Brothers moving through the ranks.

Brother typewriters have proven to be incredibly rugged and dependable. The harsh view I held of the Performer has been worn smooth by nearly three years of dependable service. I am nearly amazed at how student-proof they are. While the pile of Olivettis gets larger and larger, the brothers keep on working. In the course of repairing the few minor problems that so many of Brother's parts are completely interchangeable. Screws tend to be a uniform size. They are easy to work on because components (like the escapement) are easily accessible. The bottom line is that they can survive in my classroom and that is no easy feat.

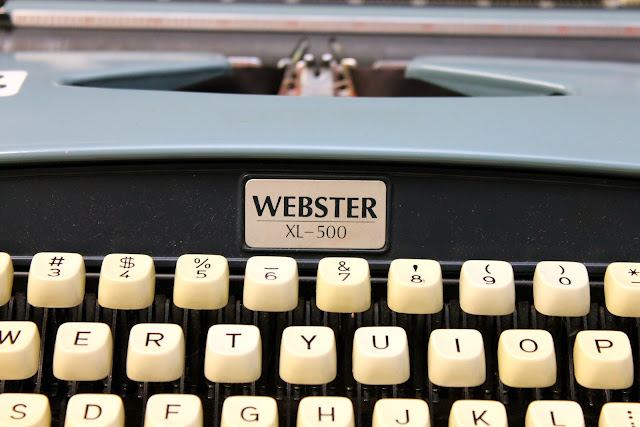

I am slowly becoming a convert. They tend to grow on you. That brings me to one of the newest typewriters to make an appearance in the classroom. Ton S. spoke about this Brother in his blog. I got an email saying that he would like to send it on to my classroom rather than keep it. I was more than happy to take it off his hands. I had a couple of Smith-Coronae that needed to be retired for repairs. That funny little clasp they use for linking the segments tends to fail under heavy use. It's one of the perennial problems with 1950s Silents and their Galaxy siblings. Ton was a gentlemen of the first order and paid to have this shipped over to me. It arrived packed incredibly well, but the carriage was freewheeling just as Ton had described in his post. The fix did not hold.

|

| Photo by I Dream Lo-Tech |

The carriage would just spring all the way over to the marginal stop. It was freewheeling in the worst way. I cracked the case open to get a closer look. Just as Ton had described, there was a hairline fracture on one end of the escapement paddle (is that what they are called?). You know, its the thing that swings into place to stop the carriage from advancing more than one space.

I could see that the crack had caused the little prong of metal to be bent back so it was not engaging with the escapement wheel teeth. I looked at it closer and as soon as I touched it the whole enchilada fell apart. It was being held on by a thread. Clearly the trip over hill and dale proved to be too much for Ton's repair. The paddle was held in place by a pivoting screw and it was very easy to remove the part and have a closer look. I was able to save the little piece that fell off.

I looked at the piece and (initially) I thought that I would try to make a new piece out of some scraps I had around here, but I noticed that there was a vertical post attached to the underside. This little bit is part of the carriage release linkage. Pressing the carriage release button presses on this post and swings the paddle out of the way of the escapement wheel. Obviously, I wouldn't be able to manufacture a piece easily so I looked to fixing the piece I had.

Glue wouldn't be strong enough unless I had a very strong and powerful glue. Something like…J.B. Weld might do the trick. I looked at the piece and saw that the break was clean. There were no gaps when the two parts were put together. I would need to make sure that the J.B. Weld bridged the break to add to the strength. Also, the piece was fairly smooth. Sanding it well to create a key would be very important.

I took out my rotary tool and used an emery bit to roughen up all the sides that would touch the epoxy. I mixed up a small amount and glued the pieces together. I was totally prepared to have this not work at all, so with apprehension I let it sit until the epoxy cured. This was what emerged 24 hours later.

I reinstalled the piece in the typewriter and it works like a charm. Time will tell how well the epoxy will hold, but the package says it is rated strong at 3,000 PSI (That is tensile strength.) with shear strength of 1000 PSI. The proof is in the pudding. It works.

The joint is the weakest part and I assume that it will only be a matter of time before it fails. This, however, will buy me time until I find a suitable replacement.

P.S. Ton, you are awesome!